Products Show

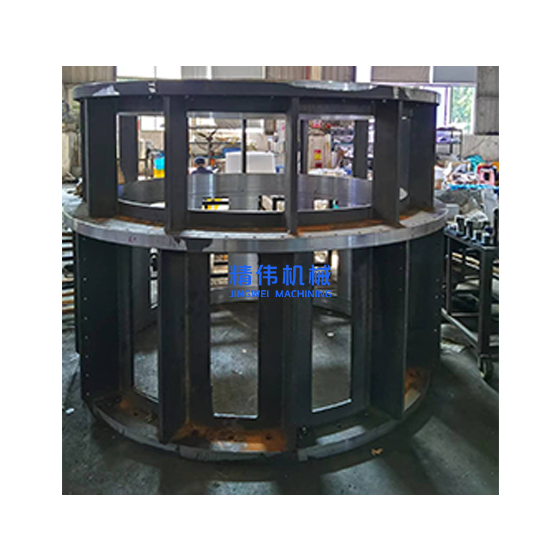

Welded structural product processing

The company is well-equipped, equipped with LCD display assembly line, as well as professional technical team, strict inspection and control, dedicated to provide global customers with precision products and professional, high-quality services.

Welded structural product processing

The company is well-equipped, equipped with LCD display assembly line, as well as professional technical team, strict inspection and control, dedicated to provide global customers with precision products and professional, high-quality services.

COMPANY INTRODUCTION

The company is located in Xiamen Tong'an Industrial Zone, with a manufacturing and processing base of more than 10,000 square meters, equipped with large-scale gantry machining centers, gantry grinders, vertical machining centers, high-speed CNC lathes, precision surface grinders, internal and external cylindrical grinders, and other large and small precision machining equipment More than 60 sets; after nearly 30 years of hard work, the company has cultivated a core team composed of excellent managers, professional technical engineers and skilled workers; at the same time, it has a professional supply chain network that has been in the same boat for many years; it has grown It is an industry leader with learning, innovation and service as its core.

Always focus on the research and development and production of panel woodworking machinery and equipment

So far, it has served tens of thousands of home furnishing companies in more than 20 countries and regions around the world.

Business advantage

Why Choose Us

News Center

What is the engraving machine?

CNC engraving and milling machine can also be called engraving machine.

What is the working principle of the engraving machine?

The engraving machine consists of three parts: the computer, the engraving machine controller, and the engraving machine host. Working principle: The design and typesetting are carried out through the special engraving software configured in the computer, and the information of design and typesetting is automatically transmitted to the engraving machine controller by the computer, and then the controller converts the information into driving stepper motor or The power signal (pulse train) of the servo motor controls the engraving machine host to generate the X, Y, Z axis of the engraving tool path base path.